We specialize in precision engineering manufacturing, focusing primarily on custom and small-series production.

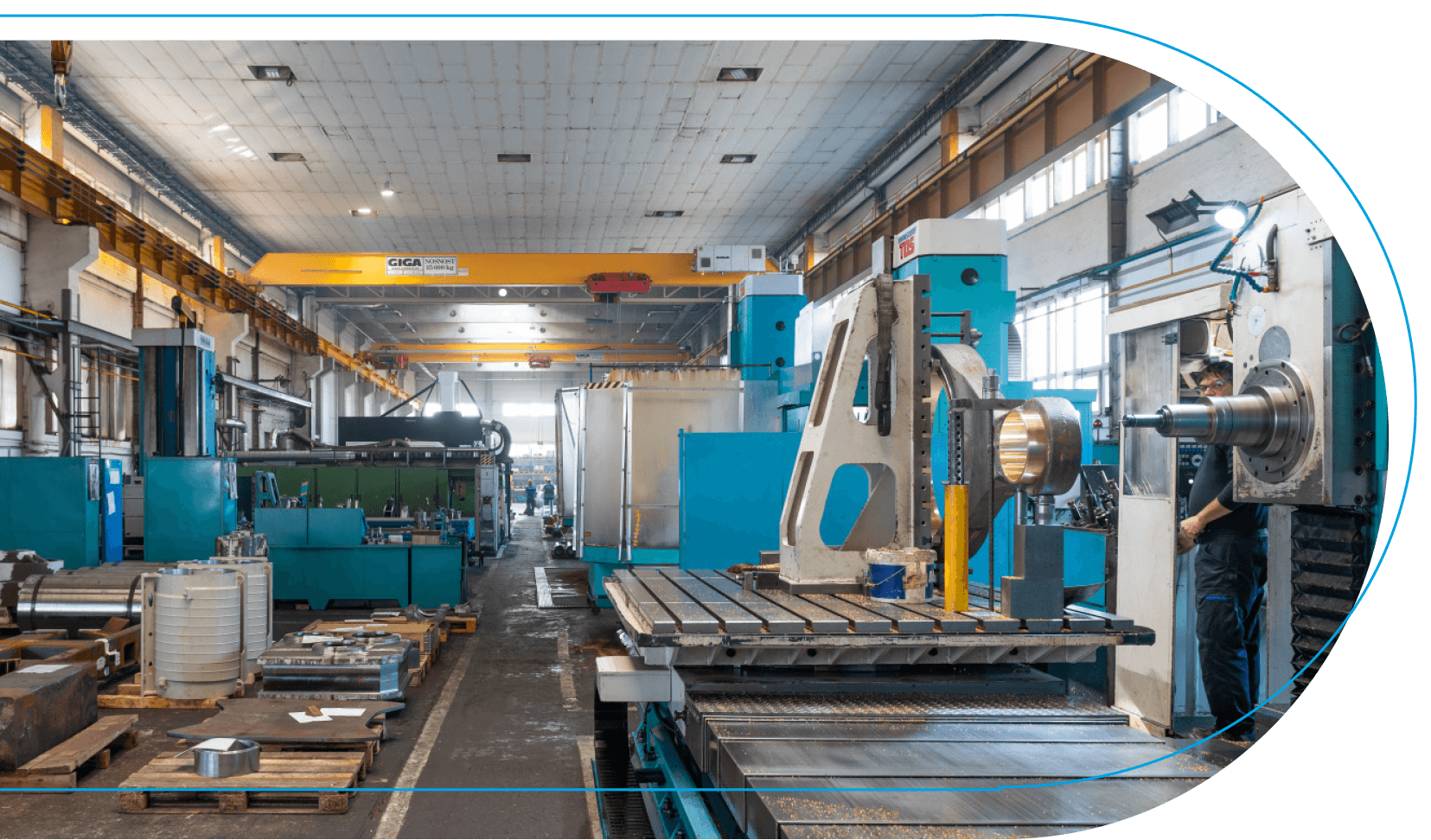

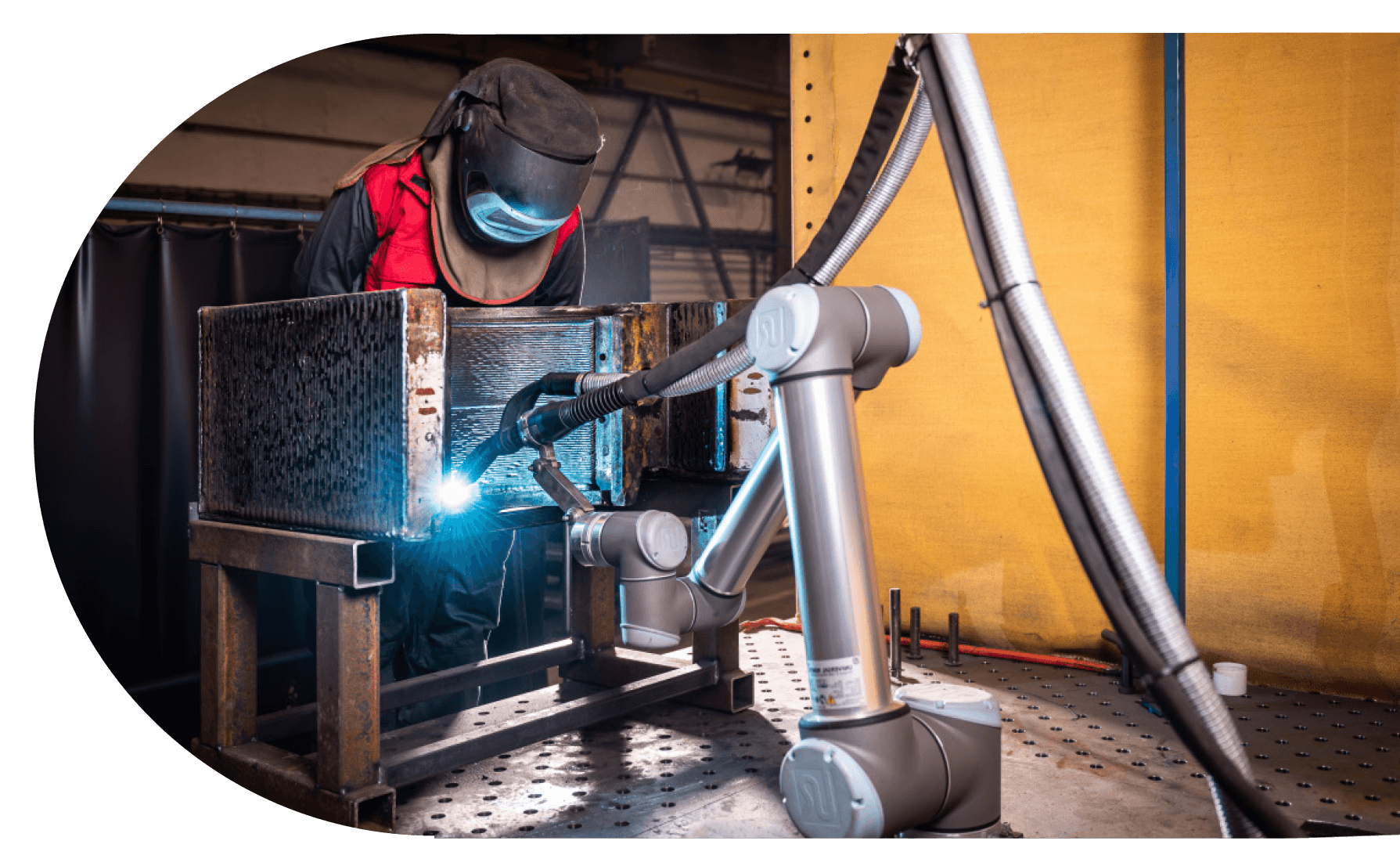

We perform machining, welding, overlay welding, repairs, and refurbishment of machine parts and equipment weighing up to 50 tons.

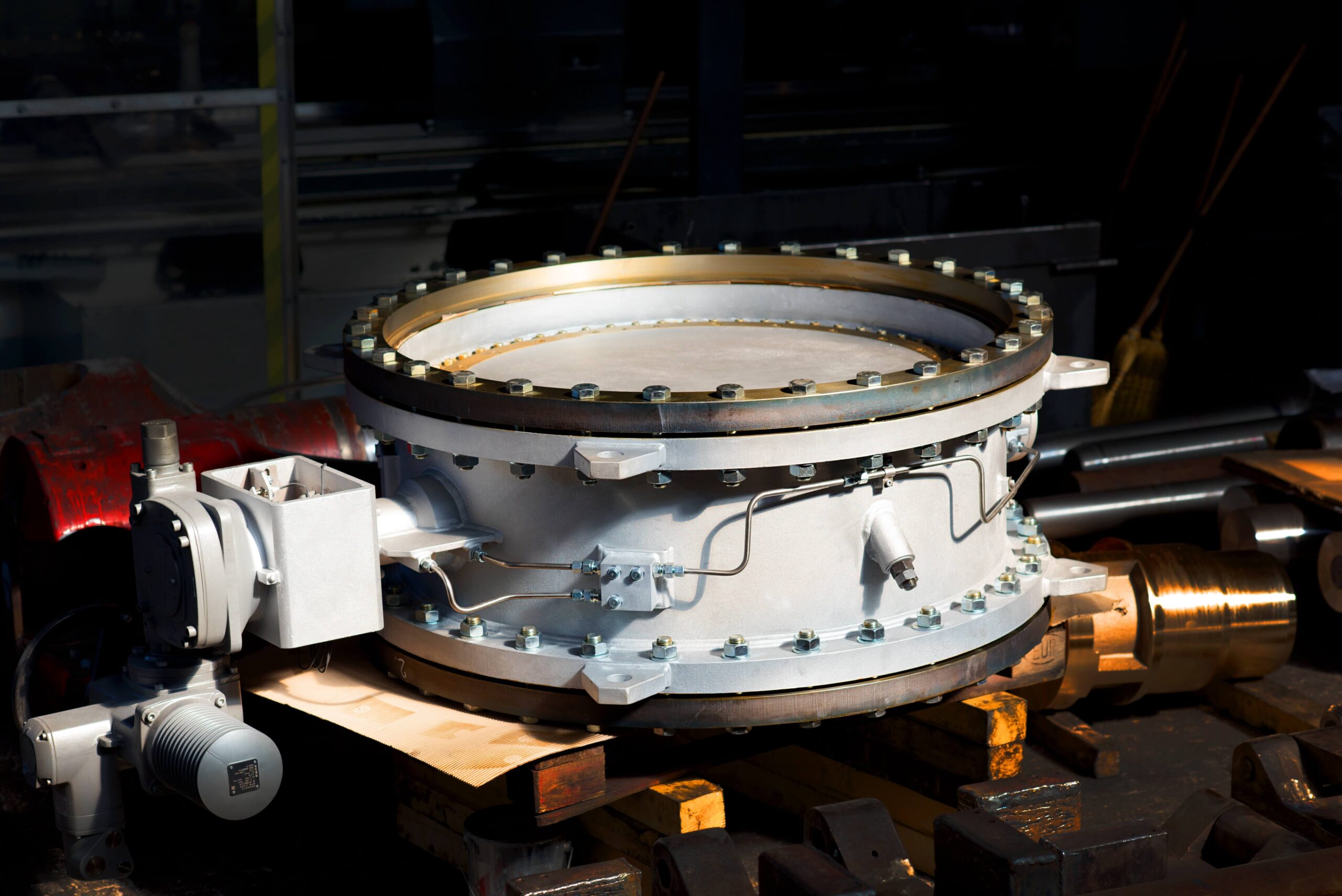

We can repair, refurbish, or manufacture new machine components based on used or damaged parts.

For the supplied products, we provide heat treatment, blasting, painting, and other technological processes associated with part or complete machine production.

We also offer assembly of machines and mechanical units from parts we manufacture or parts provided by you.

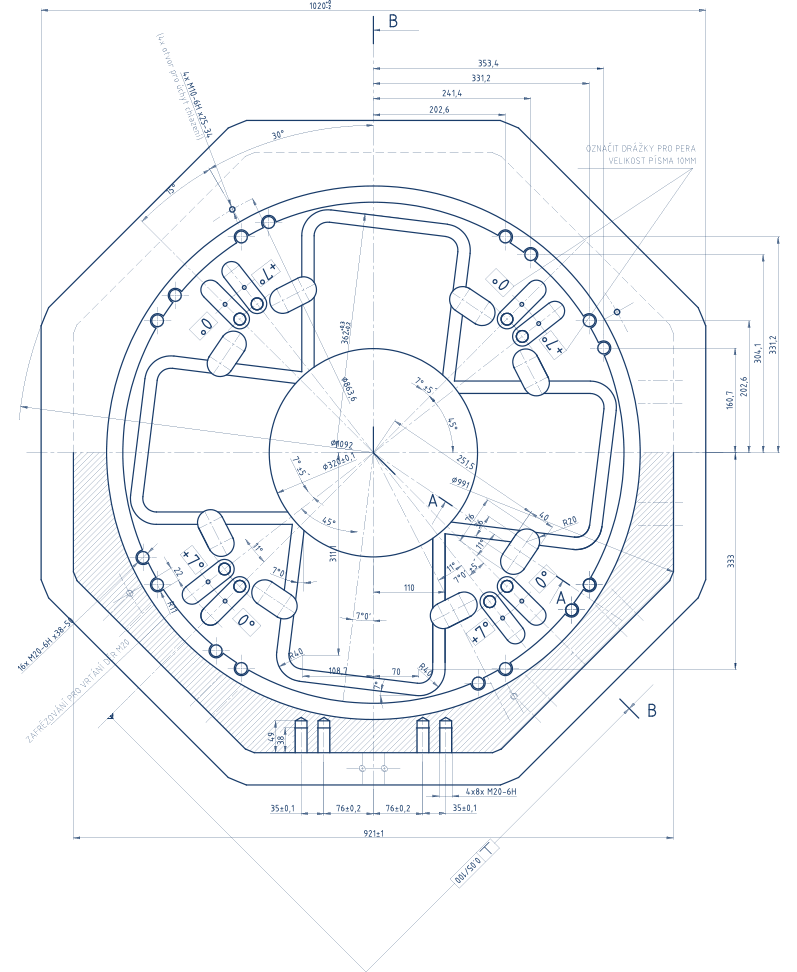

We ensure complete service, including consulting and drawing documentation for production.

We specialize mainly in prototype welding of structures, with the ability to handle components up to 50 tons.

Our welding procedure qualifications (WPQR) are certified to meet customer requirements.

Our welders and welding operators are qualified according to:

ČSN EN ISO 9606-1 + ČSN EN ISO 14732

higher welding personnel qualified under

ČSN EN ISO 14731 - EWE / EWT.

Welding procedure qualifications – ČSN EN ISO 15614-1:

- DNV-OS-C401

- Lloyd´s Register Rules + Lifting appliances

- TÜV NORD

- ČSÚ

System specification (EN):

- ČSN EN ISO 3834-2

Production specification (EN):

- ČSN EN ISO 1090-1 / 1090-2 (EXC1÷EXC4)

Other production specifications:

- AWS D1.1

Welding Technologies Used:

- 135, 136, 138 – MAG/MIG - Gas-shielded welding

- 141 – TIG - Tungsten electrode welding

- 121 – SAW - Submerged arc welding

NDT_Internal Level 2:

- VT - visual testing

- MT - magnetic particle testing

Magnetic Particle Testing:

- PT - penetrant testing

NDT_External Level 2:

- UT - Ultrasonic testing

- RT - Radiographic testing

Our external NDT suppliers are regularly checked for valid certifications.

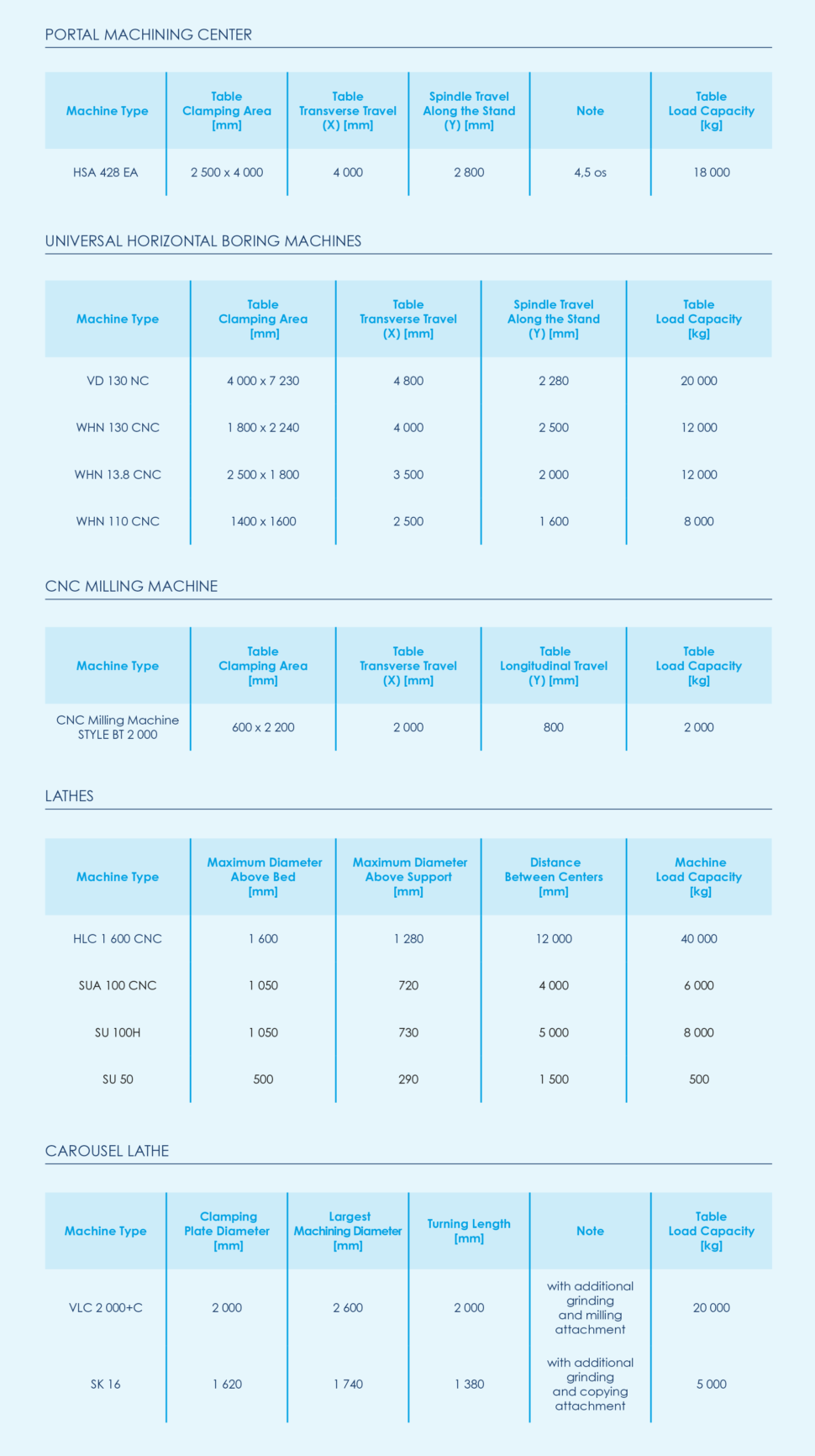

We specialize in chip machining, primarily:

- Milling of welded structures (gearbox housings, machine parts)

- Milling of castings (bearing housings, articulated couplings with ball seating)

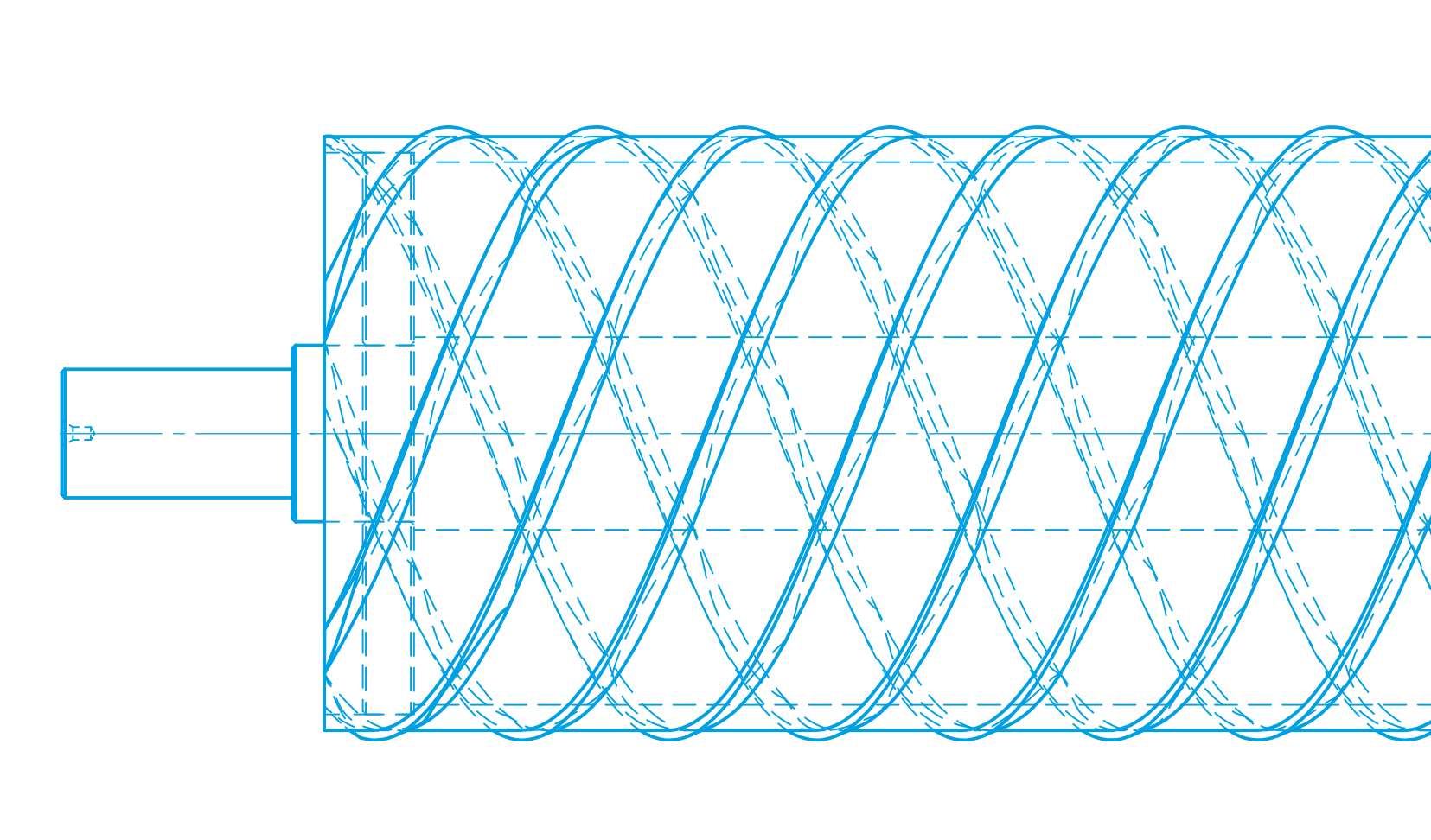

- Turning of shafts, rope drums, work rollers, calibration, straightening, transport rollers, and pulleys

- We are equipped with a wide range of milling angle heads and have extensive experience in deep drilling.

We operate two 25-ton cranes, enabling us to lift up to 50 tons.

Machining is performed on both conventional and CNC machines, including lathes, horizontal boring machines, and carousel lathes.

All machines undergo regular geometry and precision inspections.

We only use measuring instruments that are regularly calibrated by an accredited metrology company. All workpieces undergo strict final inspection, with the quality of each part documented in a dimensional report.